THE CHALLENGE!!! TO TURN ONE NIB SUPER CHAMP AND

TONS OF NIB PARTS INTO TWO SUPER CHAMPS AND

TWO SAND SCORCHERS.. LATER THIS YEAR

I WILL BE DOING THE HILUX, BLAZING BLAZER

BRUISER AND MOUNTAINEER

ALL FROM NIB'S..WATCH THE TEARS AS THE KIT

BUBBLES ARE BROKEN!!

BUT THAT IS NOT ALL. THE CARS AND TRUCKS IN THE END MUST BE PERFECT IN ALL ASPECTS OF MODELING..THEY WILL ALSO BE CUSTOM..EVERY METAL PART WILL BE BEAD BLASTED AND/OR POLISHED..SOME MAY BE VIBATORY FINISHED TO UNIFORMLY REMOVE CASTING BURRS. AFTER THE METAL IS PREPED IT WILL GET A COATING OF ELECTROLESS NICKEL, (EN). EN IS A NICKEL PHOSPHOROUS ALLOY WHICH HAS ALL THE METALURGICAL PROPERTIES OF STAINLESS STEEL..NEXT THE EN WILL BE FINISHED WITH GOLD OR RHODIUM.

|

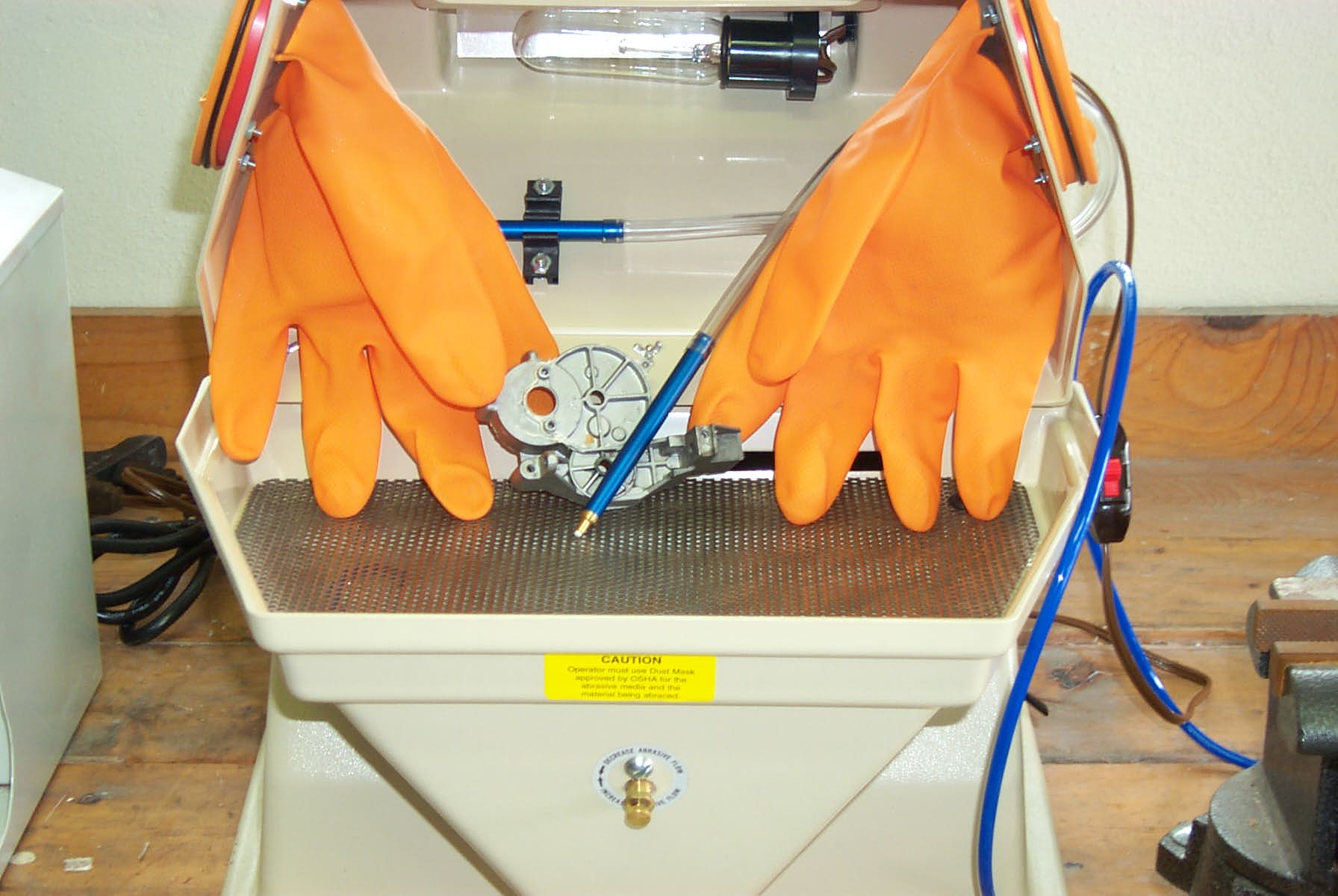

SMALL BEAD BLASTER..GREAT FOR SRB GEAR BOXES

SMALL BEAD BLASTER..GREAT FOR SRB GEAR BOXES

RHODIUM AND GOLD..RHODIUM IS A METAL THAT IS AS WHITE AS SILVER AND AS HARD AS CHROMIUM..IT WILL NEVER TARNISH AND IS VERY RESISTANT TO SCRATCHING...THE GOLD USED IS A SPECIAL FORMUALTION THAT MY COMPAY DEVELOPED..IT IS USED BY SOME OF THE WELL KNOWN ELECTRONIC AND AREO-SPACE FIRMS FOR HIGH RELIABILITY COMPONENTS. THE GOLD DEPOSIT WILL BE 10 TIMES THE THICKNESS OF CONVENTIONAL GOLD ELECTROPLATE AND WILL HAVE EXCEPTIONAL WARE RESISTANCE. THIS IS AN INDUSTRIAL GOLD SYSTEM..NOTHING LIKE THE CHEAP COATING USED ON JUNK JEWELRY AND THE VACUUM DEPOSITION ON THE FOX AND MONSTER BETTLE WHEELS.. NOW WHAT SHOULD BE RHODIUM AND WHAT SHOULD BE GOLD ON THESE CARS??....I AM LOOKING FOR OPINIONS AND SUGGESTIONS. |

THE GEAR CASE HAS NOT BEEN FINSHED.

THE GEAR CASE HAS NOT BEEN FINSHED.

.BUT GIVES A GOOD IDEA OF THE SIZE OF THE UNIT.

HERE YOU WILL SEE VIBATORY (VIB) FINISHING, BEAD BLASTING AND POLISHING OPERATONS..DEPENDING ON THE PART IT WILL SEE SOME OR ALL OF THESE PROCESSES. MOST EVERYONE IS FAMILIAR WITH BEAD BLASTING AND POLISHING..I WILL EXPAIN VIB FINISHING WHEN WE START THE PROCESS..HOPEFULLY SOME TIME NEXT WEEK. ALL OF THE EQUIPMENT I AM USING IS HOBBY SIZE FOR SMALL PARTS...THE PLATING PROCESS AS THEY SAY "DON'T TRY THIS AT HOME". I HAVE 30 YEARS EXPERIANCE IN THE CHEMICAL MANUFACTURING AND ELECTROPLATING INDUSTRY. |

YOUR BASIC POLISHING UNIT..HAS BUILT IN FILTERING SYSTEM

YOUR BASIC POLISHING UNIT..HAS BUILT IN FILTERING SYSTEM

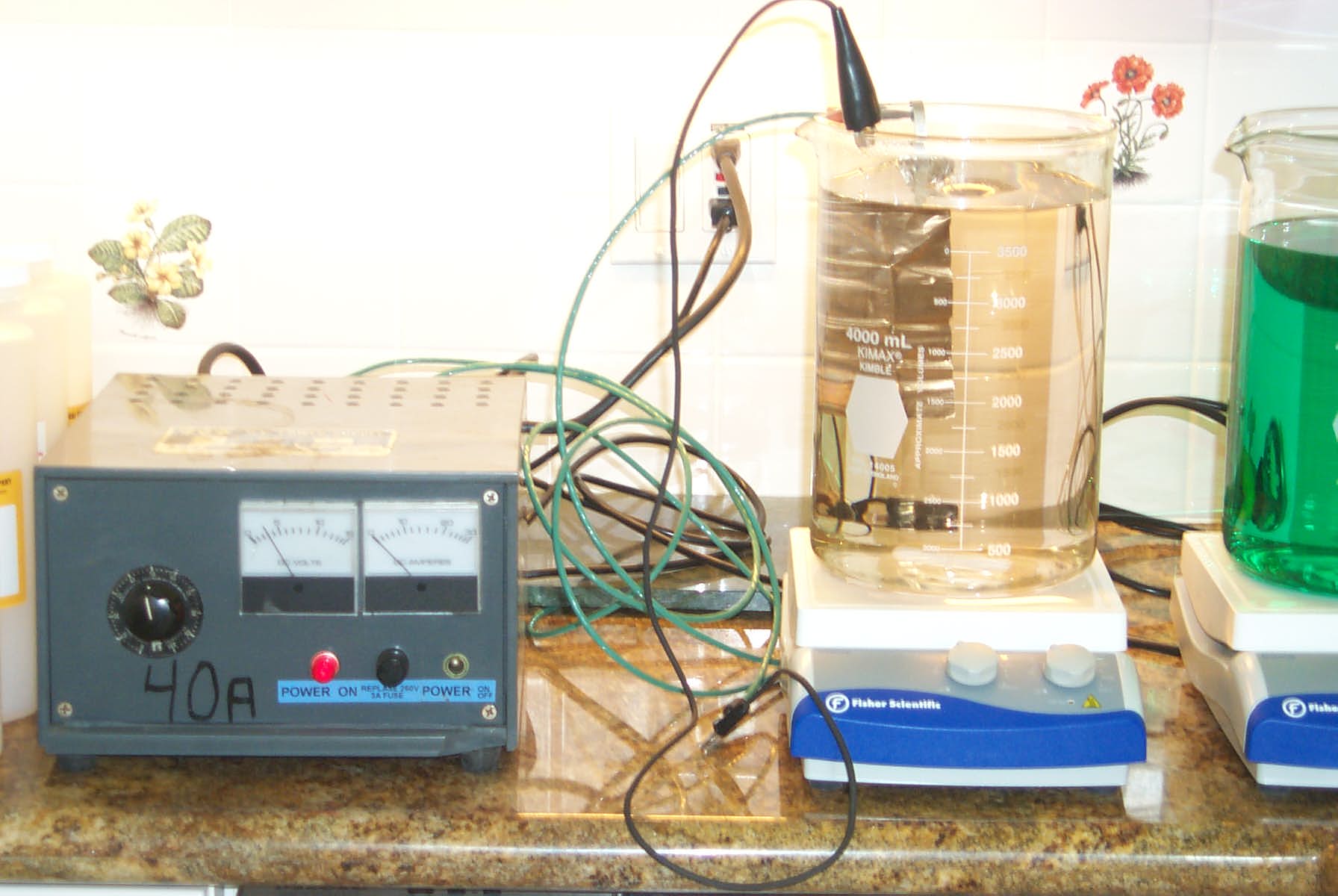

BELOW IS A SIMPLE PLATING SET UP..RECTIFIER TO SUPPLY A REGULATED DC CURRENT..HOT PLATES WITH MAGNETIC STIR BARS TO KEEP THE SOLUTION AGITATED..THE GOLD CELL REQUIRES THE RECTIFIER...THE ELECTROLESS NICKEL (EN) IS "AUTO-CATALITIC" WHICH MEAN ITS A CHEMICAL PROCESS REQUIRING NO APPLIED CURRENT.. |

THE AMBER SOLUTION IS THE GOLD CELL AND THE GREEN SOLUTION IS THE EN PROCESS

THE AMBER SOLUTION IS THE GOLD CELL AND THE GREEN SOLUTION IS THE EN PROCESS

THE EN THICKNESS WILL BE .00025 INCHES AND THE GOLD WILL BE .000050 INCHES..EN PLATES ABOUT .001 INCHES PER HOUR AND THE GOLD PLATES AT .0001 INCHES IN 50 MINUTES AT A CURRENT DENSITY OF 40 AMPS/SQUARE FOOT. |

LEFT TO RIGHT OLD PART..BEAD BLASTED PART..FINISHED PART

LEFT TO RIGHT OLD PART..BEAD BLASTED PART..FINISHED PART

COPY AND ZOOM TO GET A GOOD LOOK..

THIS CASE, BOTH HALFS, HAVE ABOUT 40 SQUARE INCHES OF SURFACE AREA..IT TAKES 17 MG/SQ" TO GET THE THICKNESS OF .000050"..GOLD COST TODAY IS ABOUT 1.3 CENTS US PER MILLIGRAM @ A 400 DOLLAR PER TROY OUNCE GOLD PRICE. SO THE GOLD VALUE ON THIS TRANNY IS ABOUT 9.00 DOLLARS US. WHEN FINISHED THE GOLD VALUE ON THE ENTIRE CAR WILL BE ABOUT 50 DOLLARS US. IT WILL TAKE ABOUT 20 MAN HOURS TO COMPLETE. |

OLD SUPER CHAMP PARTS BEFORE FINISHING

OLD SUPER CHAMP PARTS BEFORE FINISHING

PARTS AFTER BEAD BLASTING AND POLISHING,ELECTROLESS NICKEL AND GOLD ELECTROPLATE..THE ALUMINIUM TUBE WERE POLISHED FOR A MIRROR BRIGHT FINISH..I THINK THESE WILL BE RHODIUM PLATED IN THE END TO ACCENT THE GOLD SUPPORTS.. |

|

|